Rotary separators

- Mainly for separating paper or PVC trims and polyamide deposits etc. in the paper-processing (printing) industry

- Exhaust power from 3 000 m3/h to 50 000 m3/h

- Equipped with input and output channel, flaps included

- Usually attached to various types of press machines

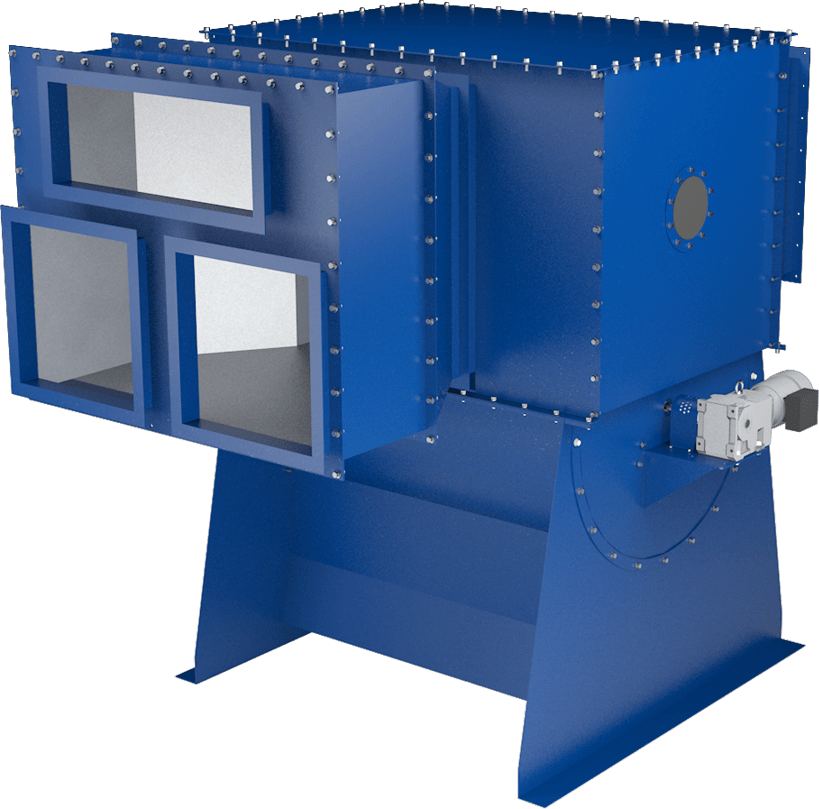

Rotary separators

These mechanic separators are used for separating fractions from the extracted material, so press machines can process them properly. Material separation takes place by catching particles on a sieve of the rotary separator. The size of the holes in the sieve depends on the size of extracted fractions and the amount of fractions the sieve is supposed to let pass through into the air extraction system, most commonly a filtration device. The separated material on the sieve of the separator is swept by rotary scraping strips (hence rotary separators) and then conveyed to the discharge. Gravitational separators are often placed on a steel structure over the container or press machine.

The most common applications

Rotary separators are most commonly used for separating paper and PVC trims, polyamide deposits and other types of materials, which are, after the separation, voluminous and thus need to be pressed. Gravitational separators remove fractions from the system, which prevents filtration devices from overloading. Rotary separators are often used in paper-processing industry, for example book productions, cardboard packaging plants etc. A common way to handle waste from the rotary separator is with a baling press, tamping press or press containers. If continuous operation of the extraction system is required, without the possibility to interrupt production to empty containers, two identical rotary separators are connected in a series with automatic changeover when a full container needs to be emptied.

Working conditions

Rotary separators are most commonly pressurized and placed in the air extraction system behind the transport fan. In special cases, when the transport fan needs to be protected from the conveyed material due to its size, the rotary separator can be placed in front of the transport fan. Maximum permissible pressure / negative pressure is ± 4000 Pa. The temperature limit of the air extracted by the rotary separator is -20 to +50°C. The revolutions of the scraping rotor need to be regulated by a frequency converter.

Power parameters of gravitational separators

Rotary separators are manufactured in power series from 3 000 m3/h up to 50 000 m3/h. A rotary separator of any power contributes to the system’s pressure loss at around 1000 to 1300 Pa.

Air volume regulation

In applications with rotary separators, exhaust power can be regulated. The change in airflow through the rotary separator does not affect the separator’s efficiency. When regulating the exhaust power, it is necessary to note the minimal air speed in the exhaust branches to prevent deposits of the extracted material from settling. This can be solved by installing multiple separate exhaust branches, which lead from the merge passage all the way to the place of extraction.

Rotary separators accessories

Standard rotary separator unit is equipped with input merger passage with flaps, output passage for connecting pipes, connecting pipes with tamping or baling press, steel construction with service platforms.

We will gladly help with your design – contact us.