Waste transport

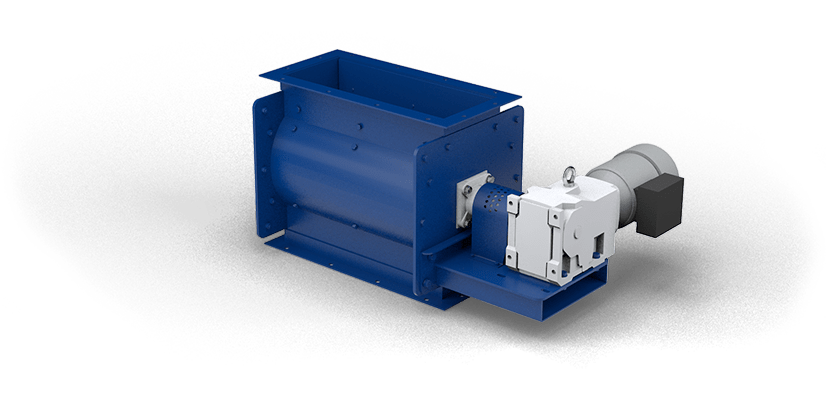

Rotary feeder

Rotary feeders are mainly used for emptying waste from filtration devices during ventilation. Rotary feeder conveys material from the upper part downwards using rotation. The rotor is equipped with flexible blades, which guarantees tight filtering conditions. The rotor is placed on the shaft using bearings, which are located outside the area of conveyed material. The revolutions of the rotor are guaranteed by an engine with transmission placed on the rotary feeder’s pedestal. Rotary feeders are mainly used for conveying dust into big-bags or containers.

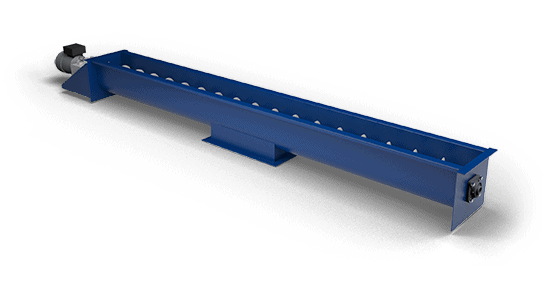

Screw conveyor

Screw conveyor is used for horizontal filtrate transport. Usually a part of dust discharge chute in larger filtration devices, where it centralizes the dust disposal output. Discharge chute of a screw conveyor is often attached to a rotary feeder, which ensures pressure separation of the inner side of the filter and the surrounding environment. Screw conveyors are designed in lengths from one up to six meters without the central bearing.

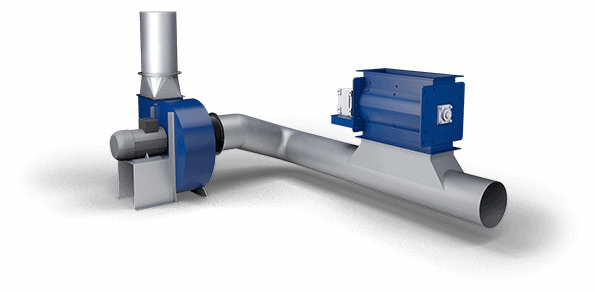

Pneumatic dust transport

Pneumatic dust transport is utilized in productions, where the separated dust needs to be conveyed to a remote storage. Pneumatic transport often consists of transport fan and a cyclone separator in a closed circuit. This system is often utilized for sawdust transport from a filtration device placed on the ground level to an adjacent storage silo. It is also utilized in welding shops and other applications, where the filtration device complicates waste manipulation. Pneumatic waste transport enables storing waste materials on an accessible place.

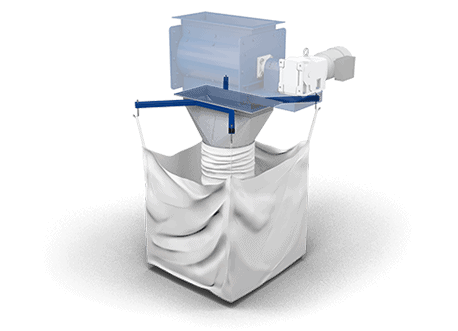

Big Bag

Big bag is utilized in filtration devices with high volume of separated dust. The advantage of big bag is its high volume of 1000 liters and a simple forklift manipulation. Big bag has an input, which can be closed by installed strings. Manipulating closed big bag is dust-free and it can be stored outside.

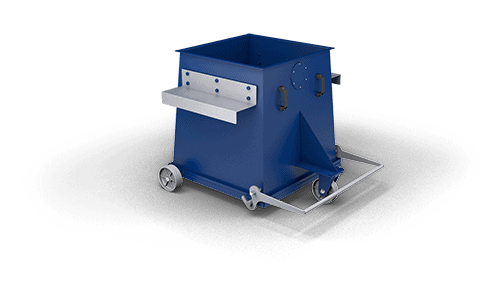

Containers with bottom discharge

Containers with bottom discharge are very frequent with our filtration units. We manufacture these containers in volumes of 150 to 300 liters. The container can be easily manipulated with a forklift or a crane. The waste discharge is usually placed on the bottom of the container using trap doors. These containers are part of the filtration unit, which they seal under pressure. Filtration unit cannot function without an attached container.

Collection containers

The smallest filtration units are equipped with containers with volumes between 30 and 55 liters. These containers can be equipped with a PVC bag for easier waste manipulation. These containers are part of the filtration unit, which they seal under pressure. Filtration units cannot function without an attached container.

We will gladly help with your design – contact us.